Bio-Based Automotive Die-Casting Lubricants: Powering Precision and Sustainability in EV Manufacturing

Bio-based die-casting lubricants are emerging as eco-friendly, high-performance solutions for precision EV parts amid rising regulatory & sustainability demands

The shift to bio-lubricants in die-casting is gaining traction as EV demands rise. Though cost and stability issues persist, regulatory pressures will drive wider adoption and innovation.”

NEWARK, DE, UNITED STATES, June 4, 2025 /EINPresswire.com/ -- 𝐈𝐧𝐭𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧: 𝐒𝐡𝐢𝐟𝐭𝐢𝐧𝐠 𝐆𝐞𝐚𝐫𝐬 𝐢𝐧 𝐃𝐢𝐞-𝐂𝐚𝐬𝐭𝐢𝐧𝐠 𝐋𝐮𝐛𝐫𝐢𝐜𝐚𝐭𝐢𝐨𝐧— Nikhil Kaitwade, Associate Vice President at Future Market Insights

As the global automotive industry accelerates toward electrification and sustainable manufacturing, the spotlight is gradually turning to less conspicuous yet critically important contributors to the process. One such element is the automotive die-casting lubricants —the high-pressure technique essential for producing intricate automotive components like engine blocks, transmission housings, and EV battery enclosures. Traditionally reliant on petroleum-based lubricants, the industry is now witnessing a subtle but significant shift. Emerging regulatory frameworks, environmental commitments, and technical performance needs are pushing manufacturers toward bio-based and eco-friendly alternatives, reshaping the way die-casting processes are designed and executed.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/REP-GB-13948

𝐓𝐡𝐞 𝐂𝐡𝐞𝐦𝐢𝐬𝐭𝐫𝐲 𝐨𝐟 𝐂𝐡𝐚𝐧𝐠𝐞: 𝐖𝐡𝐚𝐭 𝐌𝐚𝐤𝐞𝐬 𝐁𝐢𝐨-𝐁𝐚𝐬𝐞𝐝 𝐀𝐮𝐭𝐨𝐦𝐨𝐭𝐢𝐯𝐞 𝐃𝐢𝐞-𝐜𝐚𝐬𝐭𝐢𝐧𝐠 𝐋𝐮𝐛𝐫𝐢𝐜𝐚𝐧𝐭 𝐃𝐢𝐟𝐟𝐞𝐫𝐞𝐧𝐭

Unlike conventional automotive die-casting lubricant derived from mineral oils or synthetic blends, bio-based lubricants are primarily formulated from renewable vegetable oils, such as rapeseed, sunflower, or castor oil. These naturally sourced ingredients bring several advantages that go beyond their environmental credentials. Their high lubricity and superior film strength help reduce friction and wear on dies, while their inherent biodegradability significantly reduces environmental impact during disposal or accidental spillage.

One distinguishing feature of bio-lubricants is their thermal resistance. In high-pressure die casting, where molten aluminum or magnesium alloys are injected into steel molds at temperatures exceeding 600°C, thermal stability is critical. Many new-generation bio-lubricants are engineered to resist carbonization at elevated temperatures, leaving minimal residue and maintaining clean die surfaces over longer production cycles. This contributes to improved casting consistency and reduced downtime for mold maintenance.

𝐏𝐞𝐫𝐟𝐨𝐫𝐦𝐚𝐧𝐜𝐞 𝐔𝐧𝐝𝐞𝐫 𝐏𝐫𝐞𝐬𝐬𝐮𝐫𝐞: 𝐌𝐞𝐞𝐭𝐢𝐧𝐠 𝐓𝐡𝐞𝐫𝐦𝐚𝐥 𝐚𝐧𝐝 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐃𝐞𝐦𝐚𝐧𝐝𝐬 𝐢𝐧 𝐄𝐕 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠

The rise of electric vehicles (EVs) has introduced new complexities into automotive die-casting. With battery enclosures, motor housing units, and inverter casings often requiring high strength-to-weight ratios and minimal porosity, the demand for precision is greater than ever. Traditional lubricants, which may leave behind excessive residues or degrade quickly under high-cycle conditions, can hinder production consistency and part quality.

Bio-lubricants are stepping in to address these challenges. Their natural polarity improves wetting behavior on die surfaces, ensuring uniform coverage and better release properties during part ejection. This is particularly beneficial in large and intricate EV components where dimensional accuracy is non-negotiable. For example, Bühler Group, a global leader in die-casting systems, has reported ongoing trials with vegetable-based die lubricants that reduce cycle times while maintaining mold cleanliness—two crucial performance indicators in high-volume automotive manufacturing.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/automotive-die-casting-lubricants-market

𝐆𝐫𝐞𝐞𝐧 𝐌𝐞𝐭𝐫𝐢𝐜𝐬: 𝐑𝐞𝐠𝐮𝐥𝐚𝐭𝐨𝐫𝐲 𝐚𝐧𝐝 𝐄𝐧𝐯𝐢𝐫𝐨𝐧𝐦𝐞𝐧𝐭𝐚𝐥 𝐏𝐫𝐞𝐬𝐬𝐮𝐫𝐞𝐬 𝐃𝐫𝐢𝐯𝐢𝐧𝐠 𝐀𝐝𝐨𝐩𝐭𝐢𝐨𝐧

Stringent environmental regulations are playing a decisive role in reshaping the automotive die-casting lubricant market. The European Union’s REACH regulation and similar initiatives in North America have introduced restrictions on the use of certain petroleum-derived chemicals and heavy metal additives. In parallel, major automakers like General Motors and Volkswagen have outlined ambitious sustainability targets, including net-zero emissions throughout their supply chains.

Bio-based lubricants offer a viable pathway to meet these goals. Their lower volatile organic compound (VOC) emissions and non-toxic degradation profiles simplify compliance with air quality and waste disposal standards. According to a report by the International Lubricants Conference, switching from conventional to biodegradable die-casting lubricants can reduce lubricant-related environmental costs by up to 35%, factoring in waste treatment, disposal logistics, and regulatory compliance.

𝐂𝐡𝐚𝐥𝐥𝐞𝐧𝐠𝐞𝐬 𝐚𝐧𝐝 𝐑𝐨𝐚𝐝𝐛𝐥𝐨𝐜𝐤𝐬: 𝐓𝐡𝐞 𝐏𝐚𝐭𝐡 𝐭𝐨 𝐁𝐫𝐨𝐚𝐝𝐞𝐫 𝐀𝐝𝐨𝐩𝐭𝐢𝐨𝐧

Despite their benefits, bio-based lubricants face several challenges that limit their mass adoption. One of the primary concerns is cost. Vegetable oil derivatives and their associated additives tend to be more expensive than mineral oil-based counterparts. Additionally, there is lingering skepticism within parts of the industry regarding their performance consistency across different die-casting alloys and machine types.

There are also supply chain hurdles. Sourcing high-quality, stable feedstocks in large quantities requires a robust agricultural-industrial interface, which is not equally developed across regions. Furthermore, achieving long-term oxidative stability in bio-lubricants remains a technical hurdle, particularly under prolonged thermal stress.

However, manufacturers are gradually overcoming these barriers by blending bio-lubricants with synthetic esters to create hybrid formulations that combine the best of both worlds—sustainability and performance. Die longevity, reduced mold fouling, and improved worker safety in terms of reduced smoke and odor exposure are among the cumulative benefits that make the long-term business case for bio-based lubricants stronger.

𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐚𝐧𝐝 𝐈𝐧𝐬𝐭𝐢𝐭𝐮𝐭𝐢𝐨𝐧𝐚𝐥 𝐂𝐡𝐞𝐦𝐢𝐜𝐚𝐥𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/industrial-and-institutional-chemicals

𝐓𝐡𝐞 𝐑𝐨𝐚𝐝 𝐀𝐡𝐞𝐚𝐝: 𝐌𝐚𝐫𝐤𝐞𝐭 𝐅𝐨𝐫𝐞𝐜𝐚𝐬𝐭 𝐚𝐧𝐝 𝐅𝐮𝐭𝐮𝐫𝐞 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐞𝐬

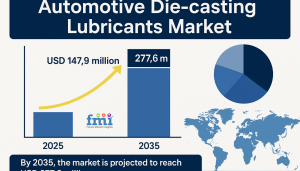

The global market for automotive die-casting lubricants is expected to grow at a steady pace, driven by expanding EV production and increased demand for lightweight metal components. According to recent data by Future Market Insights, the automotive die-casting lubricants market accounted for USD 147.89 million in the year 2025 and is expected to reach USD 277.62 million by the year 2035, at a CAGR of 6.5% during the forecast period..

Future innovations are likely to focus on smart lubrication systems that optimize the amount and frequency of lubricant application, further enhancing efficiency and sustainability. Nanotechnology, enzyme-enhanced biodegradation, and blockchain-based traceability for lubricant sourcing are also on the horizon, pointing to a much more sophisticated ecosystem than the one that existed a decade ago.

As automakers move beyond the mold—literally and figuratively—the integration of sustainable die-casting lubricants is no longer a fringe idea but a strategic imperative. Those who adapt early stand to gain not only environmental goodwill but also operational excellence in an increasingly competitive industry.

𝐀𝐮𝐭𝐨𝐦𝐨𝐭𝐢𝐯𝐞 𝐃𝐢𝐞 𝐂𝐚𝐬𝐭𝐢𝐧𝐠 𝐋𝐮𝐛𝐫𝐢𝐜𝐚𝐧𝐭𝐬 𝐌𝐚𝐫𝐤𝐞𝐭 𝐛𝐲 𝐂𝐚𝐭𝐞𝐠𝐨𝐫𝐲

By Lubricant Type:

- Die-Casting Lubricant

- Plunger Lubricant

By Type:

- Water-based

- Solvent Based

- Other

By Die-Casting Material:

- Aluminum

- Magnesium

- Zinc

- Other

By Region:

- North America

- Latin America

- Europe

- East Asia

- South Asia & Pacific

- Middle East & Africa (MEA)

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Chlorine Compressors Market: https://www.futuremarketinsights.com/reports/chlorine-compressors-market

Wind Turbine Gear Oils Market: https://www.futuremarketinsights.com/reports/wind-turbine-gear-oils-market

Honing Oil Market: https://www.futuremarketinsights.com/reports/honing-oil-market

Laminating Adhesives Market: https://www.futuremarketinsights.com/reports/laminating-adhesives-market

N-Methyl Pyrrolidone (NMP) Market: https://www.futuremarketinsights.com/reports/n-methyl-pyrrolidone-nmp-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.